International Conferences on Composite Materials

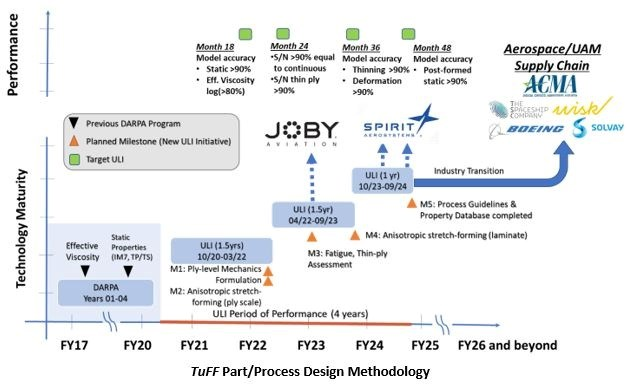

International Conferences on Composite Materials composite.sciencefather.com Award Nomination - https://x-i.me/compram1 Abstract Submission - https://x-i.me/compabst2 UD researchers advance TuFF composite's viability for aerospace TuFF — tailored universal feedstock for forming — is a strong, highly aligned, short-fiber composite material that can be made from many fiber and resin combinations. Created at the University of Delaware’s Center for Composite Materials (UD-CCM, Newark, U.S.), it can be stamped into complex shapes, just like sheet metal, and features high-performance and stretchability up to 40%. Since its introduction, CCM researchers have explored applications for TuFF, from materials for repairing U.S. pipelines to uses in flying taxis of the future (see “… TuFF composite material shows high potential for UAM ” and “ UD’s Center for Composite Materials hosts NASA University Leadership Initiative ”). Now, armed with $13.5 million in funding from the U.S. Air Force,