Posts

Showing posts from June, 2023

9th Edition of International Conferences on Composite Materials, 27-28 J...

- Get link

- Other Apps

International Conferences on Composite Materials

- Get link

- Other Apps

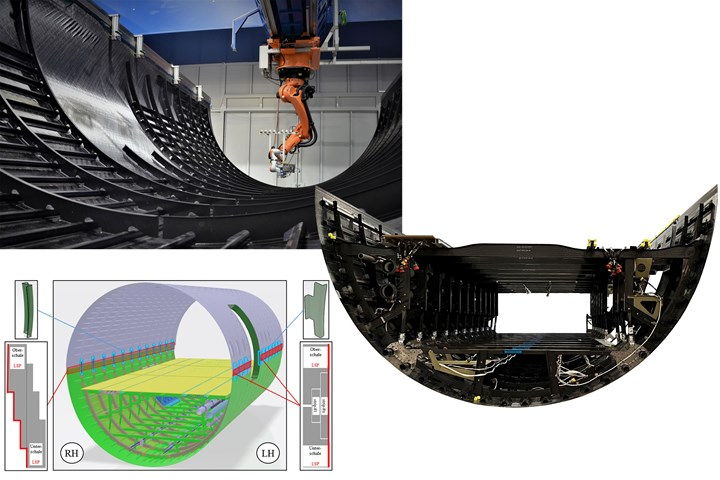

9th Edition of International Conferences on Composite Materials composite.sciencefather.com Award Nomination - https://x-i.me/compram1 Abstract Submission - https://x-i.me/compabst2 Manufacturing the MFFD thermoplastic composite fuselage The Multifunctional Fuselage Demonstrator (MFFD) program was conceived in 2014 as one of three large aircraft demonstrators within the EU-funded Clean Sky 2 (CS2) initiative (now Clean Aviation) aimed at advancing innovative technologies, aircraft sustainability and a competitive supply chain in Europe. When disseminated in 2017, the MFFD program goals were ambitious: Build an 8-meter-long, 4-meter-diameter fuselage section fully from carbon fiber-reinforced thermoplastic polymer (CFRTP) composites to enable production of 60-100 aircraft/month with a 10% reduction in fuselage weight and 20% cut in recurring cost. By the project’s end in 2024, overall technology readiness level (TRL) for such a fuselage will be advanced to TRL 5. From 2017-2019, Air

International Conferences on Composite Materials

- Get link

- Other Apps

8th Edition of International Conferences on Composite Materials composite.sciencefather.com Award Nomination - https://x-i.me/compram1 Abstract Submission - https://x-i.me/compabst2 PRF Composite Materials launches Reepreg composite As part of a portfolio of products designed to deliver improved sustainability, PRF Composite Materials (Poole, Dorset, U.K.) is introducing Reepreg, the company’s new carbon fiber prepreg material made with recycled chopped carbon mat. PRF’s processing enables almost full impregnation, which makes Reepreg drapeable and easily handled by the constructor, without falling apart when used — a feature that the PRF team believes sets it apart from other recycled mat products available. The mat is made using recycled carbon fiber prepreg waste. In the near future, PRF says the the finished component — including scrap from trimming components — will also be recyclable, thus improving circularity and extending the life cycle of this product. Reepreg will be av

International Conferences on Composite Materials

- Get link

- Other Apps

8th Edition of International Conferences on Composite Materials composite.sciencefather.com Award Nomination - https://x-i.me/compram1 Abstract Submission - https://x-i.me/compabst2 Chemical simulation to achieve sustainable composite materials testing Software company Molydyn (Bristol, U.K.) is to use chemical simulation to test new composite materials, in collaboration with the University of Sheffield Advanced Manufacturing Research Centre (AMRC, Catcliffe, U.K.) and Bitrez Ltd. (Wigan, U.K.), a designer and manufacturer of specialist polymers and resins, in order to make the testing process more sustainable. The project aims to use molecular modeling to develop a viscosity modeling capability for Molydyn’s accessible web simulation platform, Atlas, to help design better composite materials while reducing costs and environmental impact. Built upon previous collaborations with the AMRC, the project is funded by an Innovate UK Transformative Technologies grant. Chemical simulation

Composites Applications | Awards and Conferences | Composite Materials |...

- Get link

- Other Apps

International Conferences on Composite Materials

- Get link

- Other Apps

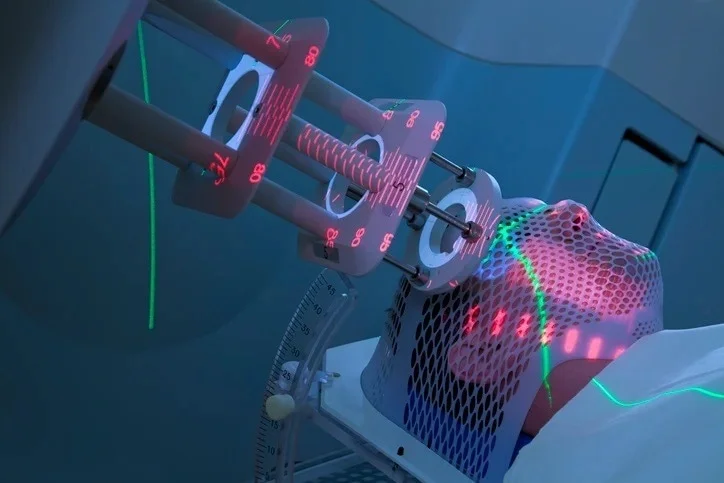

8th Edition of International Conferences on Composite Materials composite.sciencefather.com Award Nomination - https://x-i.me/compram1 Abstract Submission - https://x-i.me/compabst2 Novel Composite Proven Efficient in Cancer Treatment At the little-explored intersection of organic and inorganic chemistry, a new material made could not only allow highly powerful solar panels but could also guide the next generation of cancer treatments. Having been explained in a Nature Chemistry journal that has been recently reported, the composite is composed of ultra-tiny silicon nanoparticles and an organic element directly linked to those utilized in OLED televisions. It has the potential to increase the speed with which two molecules have the potential to exchange energy and transform lower-energy light into higher-energy light. Just a handful of laboratories in the world have the potential to make silicon nanoparticles with the correct specifications. One of those laboratories has been gui

Assoc Prof Dr. Jingming Cai, Southeast University, China, Best Researche...

- Get link

- Other Apps

International Conferences on Composite Materials

- Get link

- Other Apps

8th Edition of International Conferences on Composite Materials composite.sciencefather.com Award Nomination - https://x-i.me/compram1 Abstract Submission - https://x-i.me/compabst2 New Plant-Derived Composite Is Tough as Bone and Hard as Aluminum The strongest part of a tree lies not in its trunk or its sprawling roots, but in the walls of its microscopic cells. A single wood cell wall is constructed from fibers of cellulose—nature’s most abundant polymer, and the main structural component of all plants and algae. Within each fiber are reinforcing cellulose nanocrystals, or CNCs, which are chains of organic polymers arranged in nearly perfect crystal patterns. At the nanoscale, CNCs are stronger and stiffer than Kevlar. If the crystals could be worked into materials in significant fractions, CNCs could be a route to stronger, more sustainable, naturally derived plastics. Now, an MIT team has engineered a composite made mostly from cellulose nanocrystals mixed with a bit of synt

Carbon Fiber | Awards and Conferences | Composite Materials | ScienceFat...

- Get link

- Other Apps