International Conferences on Composite Materials

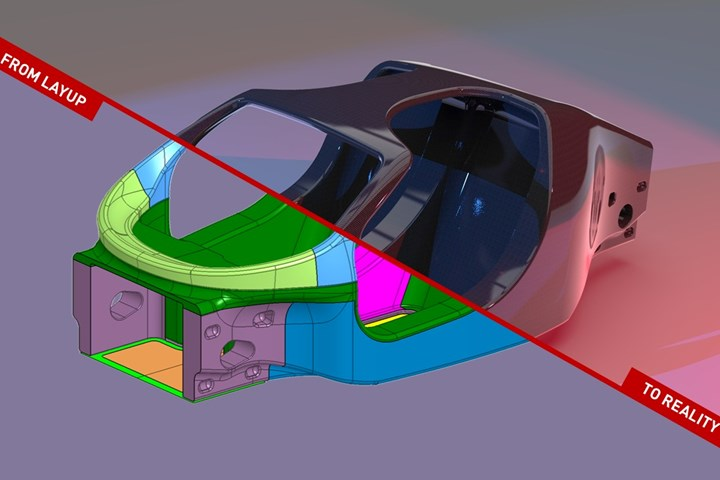

International Conferences on Composite Materials composite.sciencefather.com Award Nomination - https://x-i.me/compram1 Abstract Submission - https://x-i.me/compabst2 The Native Lab launches composites course training membership plan For 2023, The Native Lab (TNL, Madrid, Spain) is set to expand its course catalog, adding new courses on composites, and launching updated versions of older, past ones. TNL’s website platform currently includes five self-paced, instructor-led online courses. By the end of 2023, TNL anticipates eight online courses to be available. To ensure students (individually or through a company) can access as many courses as possible, TNL has launched a new training membership plan called The Native Lab PRO. The membership guarantees access to all online courses available on the platform. It works with a subscription fee of €699/year. This includes Composite Materials , Monocoque Design , Monocoque Structural Analysis , Catia Design Methodology and Applied