Researchers Create a Bacterial Cellulose Composite with Added Graphene Oxide

Researchers Create a Bacterial Cellulose Composite with Added Graphene Oxide

Background

Cellulose, a readily available and cheap biopolymer synthesized by plants, is primarily obtained by recycling used paper and processing deciduous and coniferous trees. However, supporting substances, such as hemicellulose and pectin, typically co-exist with plant-based cellulose.

Although such a chemical composition does not adversely impact the application potential of plant-based cellulose (PC), products with 100% cellulose content, such as BC, are often preferred over PC when used as a biomaterial.

Different bacteria, including Gram-positive bacteria such as Sarcina and Gram-negative bacteria such as Agrobacterium and Gluconacetobacter xylinus, can synthesize BC. Almost 59 bacterial strains from ripe vegetables and fruits can synthesize BC.

Cellulose with better structural and physicochemical properties can be synthesized in vitro using the cell-free enzyme system that employs enzymes derived from fungi or bacteria. The cell-free method is more efficient and uses less glucose compared to the bacteria-based methods, and the resulting fibers possess larger diameters.

The BC synthesis mechanism influences specific properties of cellulose, including the degree of polymerization and crystallinity, mechanical strength, porosity, water holding capacity, and biodegradability.

BC can store, absorb, and desorb large amounts of water as a hydrogel owing to its nanofiber structure makes BC an exceptional biomedical material. BC can also form composite materials when combined with biopolymers such as collagen, chitosan, or alginates.

Composites such as BC/chitosan composite were already synthesized as a dressing material to treat different ulcers, wounds, and burns, while BC/alginate composites were used for tissue engineering.

BC can be modified using ex-situ and in situ methods to introduce undescribed and new properties. The in-situ method involves the addition of water-soluble nanoparticles or additives directly into the culture medium to modify BC.

Several studies demonstrated BC modification using electrically conductive polymers and carbon nanoadditives, such as GO or graphene, and electrically conductive polymers through the in-situ method.

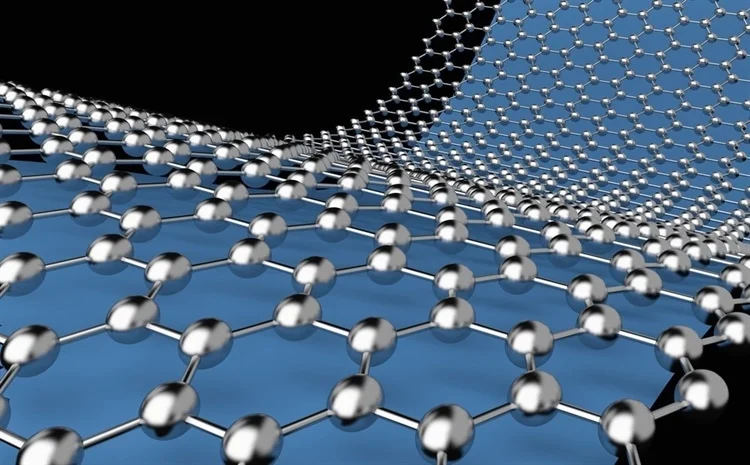

The modification using carbon nanoadditives increases the porosity and specific surface area and improves the strength of the composite. GO has specifically gained attention among carbon nanoadditives for the synthesis of BC composite as the two-dimensional (2D) material strongly links to BC by forming hydrogen bonds.

Several BC/GO nanocomposites with multiple conformations were developed for different applications in the field of biomedicine. For instance, graphene oxide was used as a delivery carrier for medicines or genes and to develop biosensors.

The Study

In this study, researchers synthesized BC/GO composite membranes with different concentrations of GO using an in-situ method and investigated the influence of GO nanoparticles on the properties and structure of the synthesized membranes.

Researchers also investigated the feasibility of using the synthesized composite membranes as a potential active dressing with the sustained-release analgesic paracetamol. Paracetamol was selected for the in-vitro biologically active substance sorption study as it is a strong antipyretic and analgesic medicine.

Microorganisms obtained from the Golden Delicious apple vinegar were utilized to synthesize the BC. No additional nutrients were added for bacterial growth. Additions such as citric acid, yeast extract, and peptone were not used for cellulose biosynthesis.

A liquid sucrose medium with a 110 g/L concentration was prepared and sterilized at 121 oC in an autoclave for 15 min. Subsequently, 200 mL of apple cider vinegar, a 1 × 1 cm fragment of “mother of vinegar” containing live bacteria, yeast, and BC, and 800 mL of liquid sucrose medium were placed in a 2000 mL sterilized laboratory beaker and thoroughly mixed.

The resultant mixture was divided into four parts and placed in sterilized beakers. Every beaker was then covered with a watch glass and transferred to an incubator preheated to 25 oC. The BC/GO composite synthesis was performed for 12 days by adding different amounts of GO dispersion to each of the four samples.

The concentration of GO was maintained at 50 ppm to facilitate the synthesis. BC/GO composite membranes with 3.7%, 5.4%, and 7.1% of GO were designated as BC/GO/I, BC/GO/II, and BC/GO/III, respectively. The purification of the synthesized membranes was performed using a 2% w/w aqueous solution of potassium hydroxide (KOH) and distilled water.An electronic micrometer screw and an electronic thickness gauge were employed to measure the thickness of the wet BC/GO membranes and dry BC/GO membranes, respectively. The water content in wet samples and water absorption in dry samples were measured using a laboratory electronic moisture balance.

The bioactive substance release kinetics from the membranes were studied in-vitro in phosphate-buffered saline (PBS) that mimics the pH, osmolarity, and ion concentration of human body fluids.

Four solutions containing PBS as a solvent and 20.0, 10.0, 5.0, and 2.5 ppm paracetamol were prepared and then the desorption and sorption of paracetamol from the synthesized membranes were investigated. Tests performed using dry membranes were unsuccessful. Thus, these experiments were performed using wet membranes as carriers of paracetamol.

Scanning electron microscopy (SEM), Fourier transform infrared (FTIR) spectroscopy, wide-angle X-ray scattering (WAXS) studies, and thermogravimetric analysis were performed for the characterization of membranes.

Comments

Post a Comment