International Conferences on Composite Materials

International Conferences on Composite Materials

Award Nomination - https://x-i.me/compram1

Abstract Submission - https://x-i.me/compabst2

Manipulate a Composite Material by Means of Heat and Magnetic Fields

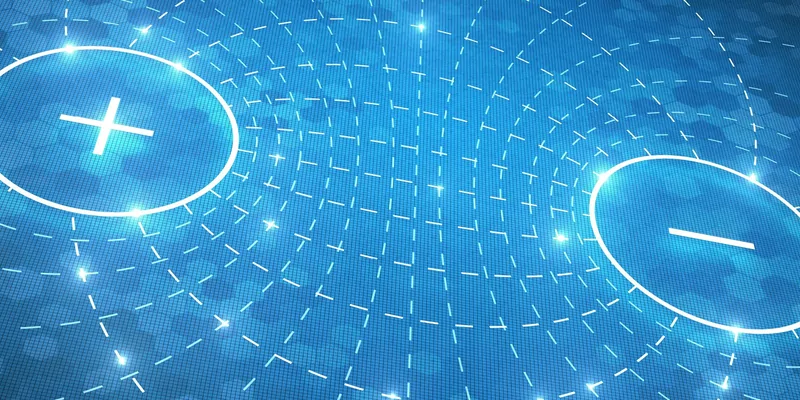

Researchers from the Public University of Navarre (UPNA/NUP), that belong to the Smart Cities (ISC) and InaMat2 institutes, have remotely manipulated a composite made of thermoplastic and iron powder using heat and magnetic fields, achieving “a degree of control never seen before.” The composite, which is classified as programmable matter, can be remotely manipulated in air, water, or inside biological tissue, thus opening up possibilities for the development of biomedical devices, tactile displays, and object manipulators.

Control of matter using heat and magnetic fields

The UPNA/NUP researchers used a composite of thermoplastic and iron powder. The former is rigid at 27°C, but becomes malleable when heated in a process that is reversible; on the other hand, iron powder can be mixed with the thermoplastic and is attracted by magnetic fields. The compound was subjected to thermal patterns and magnetic fields. Thanks to this combination, “an unprecedented degree of control is demonstrated,” according to the article's lead author, Josu Irisarri. To do this, the compound is heated at specific locations which become malleable and can be attracted by magnetic fields. “The hot areas solidify when they cool down and the process can be repeated,” adds Josu Irisarri.

The researchers performed multiple remote manipulations using light, heat, and magnets on the composite. For example, a filament was heated at the center, making it malleable. Afterwards, a magnetic field pulled from the sides to bend it along the pre-heated area. The filament solidified upon cooling down. This process was repeated several times to form different letters using a single strand.

In a second experiment, a sheet of material was heated up by a laser at specific points. Afterwards, a magnetic field attracted these points and, as they cooled down, they became solid forming a Braille pattern. This process was repeated for more complex patterns.

Comments

Post a Comment