Perspectives on the robustness of the mechanical properties assessment of biocomposit

Biocomposite materials made of natural plant fibers are becoming a viable alternative to the use of synthetic ones such as glass fibers, thanks to many economic, ecological, and technical benefits. However, their massive use in the industry requires optimal control of their mechanical performances, which constitutes a real scientific issue to be overcome. Indeed, biocomposites suffer from an important variability in their mechanical properties because of their multiscale structure, natural growth conditions, and various processing parameters, in addition to eventual chemical treatments. Biocomposites are also highly sensitive to the surrounding environment in terms of humidity and temperature because of the hydrophilic properties of natural plant fibers. In this context, this Perspective aims to provide a critical look at the influence of the main factors that affect the mechanical properties of biocomposites in order to suggest some possible research outlooks that could contribute to optimizing the control of these mechanical properties and expanding the use of biocomposites in industry.

I. INTRODUCTION

Global warming and climate change are nowadays the concern of the political and economic world. The main challenge is to reduce greenhouse gas emissions through the development of eco-friendly materials and sustainable manufacturing processes.1 To reach this objective, many industrial sectors are moving toward a bio-economy by using biomaterials such as biocomposites, instead of conventional synthetic composites made with glass or carbon fibers.2,3 Biocomposites are elaborated with natural plant fibers such as flax, hemp, or jute fibers. Biocomposites can be called “green composites” if the polymer matrix is also bio-based such as polylactic acid (PLA). The resulting green composites are then 100% bio-based and compostable.4

Natural plant fibers can mechanically compete with synthetic glass fibers in terms of stiffness. Indeed, bast fibers such as flax or hemp are characterized by an elastic modulus comparable to that of glass fibers while being lighter.5 This results in a specific elastic modulus of bast fibers greater than that of glass fibers, which is a significant parameter in choosing materials that meet the new environmental constraints in terms of energy efficiency and CO2 emission.

However, an assessment of the mechanical properties of biocomposites is still challenging because of the complex structure of plant fibers. Indeed, natural plant fibers suffer from different issues, typically the variability of their mechanical properties resulting from their natural characteristics, growth conditions, and multiscale complex cellulosic structure, which implies the consideration of the analysis scale for mechanical characterization.6 Furthermore, the hydrophilicity of plant fibers due to the presence of hydroxyl groups in their cell walls leads to poor interface generation with polymer matrices and moisture absorption into the fiber structure from a humid environment.7 This moisture absorption contributes, in general, to a modification in the mechanical properties of the resulting composite depending on the analysis scale due to different mechanisms such as plasticization, creeping of microfibrils, and polymer hydrolysis.8 Moisture diffusion into the composite is also accelerated by the increase in the surrounding temperature. Therefore, considering the hygrothermal aspect in the mechanical characterization of biocomposites at different scale levels is mandatory to conduct an efficient analysis and to be able to improve correctly the mechanical properties of these eco-friendly materials.

In this context, this Perspective aims first to give a critical overview of the multiscale mechanical properties of biocomposites, the hygro-mechanical properties, in addition to the hygrothermal coupling effect. Then, a discussion will be carried out on the possible solutions to analyze efficiently the mechanical properties of biocomposites by considering the multiscale hygrothermal effect in order to master, control, and improve the functionalities of biocomposite parts and meet the industrial specifications.

II. MULTISCALE MECHANICAL PROPERTIES OF BIOCOMPOSITES

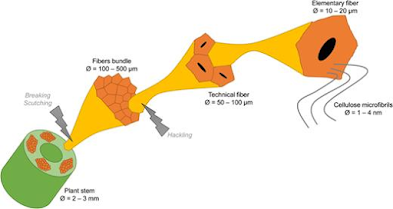

As shown in Fig. 1, natural bast fibers are extracted from plant stems in the form of bundles that are located at the periphery,9 playing the role of mechanical support for the stem. The extraction is, in general, carried out mechanically by scutching to separate the bundle from the rest of the stem.10 Fiber bundles are then subjected to hackling for separating them into smaller bundles that are called technical fibers, which are the conventional form of natural fibers used in polymer composites. Each technical fiber is composed of a few elementary fibers gathered together via pectic interfaces.9

Therefore, many key factors can influence the mechanical properties of the resulting biocomposites, among which we can first find the growth conditions of plants, the multiscale cellulosic structure of plant fibers, the extraction conditions from plant stems, the eventual chemical treatment of the fibers, the environmental conditions in terms of humidity and temperature, and the processing parameters of the biocomposite parts. All these factors and their effects lead to induce a high variability in the mechanical properties of plant fibers and, hence, complicate an efficient assessment of the mechanical properties of the resulting composites. Indeed, the complexity in the case of natural plant fibers lies in the fact that the main components of an elementary fiber (cellulose, hemicellulose, and lignin) are present in variable proportions for the same fiber type,14 which impacts the quality of the resulting fibers. It is dependent on many factors such as the climatic conditions of growth (rainfall, sunshine, etc.), the cultivation conditions (compost, fertilizer, etc.), and the harvesting process.This variability in composition contributes to the variability in the mechanical properties obtained by conventional tensile tests because the mechanical properties of cellulose, hemicellulose, lignin, and pectin show a highly significant difference.14,16 For example, it has been shown in a literature review5 that the tensile modulus of flax fibers varies from 28 to 100 GPa, while their tensile strength varies from 343 to 1035 MPa. For hemp fibers, the tensile modulus varies from 32 to 60 GPa, while the tensile strength varies from 310 to 900 MPa. For jute fibers, the tensile modulus varies from 25 to 55 GPa, while the tensile strength varies from 393 to 773 MPa. The variability is among the important issues that the composite industry can face because the mechanical properties of biocomposite parts must meet the industrial standard that cannot be adapted each season to the updated mechanical properties of the cultivated plant fibers. This issue limits their massive use in industrial applications.

On the other side, the multiscale structural organization of biocomposites from cellulose microfibrils of elementary fibers to the whole macrostructure of the composite leads to an important variability of the mechanical properties in the same composite material, depending on the testing method and the analysis scale. It has been demonstrated in previous work6 that the increase of the geometrical contact scale when performing nanoindentation experiments on flax fibers (i.e. the increase of the tip indenter radius) contributes to an important increase of the elastic modulus due to the increase of the cellulose microfibrils involved by compression on the mechanical contact as shown in Fig. 3, while the elastic modulus of the polypropylene matrix (PP) has not revealed a significant variation when increasing the edge radius of the tip indenter. Tensile tests provide higher elastic modulus values because all cellulose microfibrils of the elementary fiber are involved by tension to mechanical contact.

The mechanical properties of biocomposites are then influenced by the natural character of plant fibers and the mechanical analysis scale. The natural growth process of plant fibers is difficult to control because it depends on the climatic and earth conditions of growth. Therefore, it cannot be guaranteed that plant fiber cultivation of the current year will be similar to that of the previous year or next year.18 For all these reasons, plant fiber production industries must harmonize and master the mechanical properties of plant fiber to be able to provide standard technical fibers with controlled specifications. Mixing the cultivation of several successive seasons could reduce the apparent variability in the mechanical properties. However, this variability will still exist at the microscale in the fibrous structure and will consequently increase the random anisotropy of the biocomposite.

In our point of view, in-depth scientific work should be carried out first to determine if there is a functional relationship between the growth conditions of plant fibers and their resulting mechanical properties and/or their chemical composition by keeping the extraction process constant. If so, this will indicate that the maximum control of growth conditions of plant fibers must be carried out and this is obviously not an easy task to achieve. Controlling efficiently the growth conditions means applying artificial climatic conditions in terms of temperature, humidity, and watering, instead of natural ones by carrying out the cultivation in greenhouses, which could considerably raise the production cost. Moreover, sun radiation is complicated to reproduce artificially and cannot be controlled similarly each year, which may induce variability in the microstructure of plant fibers and their mechanical properties. Therefore, the effect of sun radiation on the microstructure and mechanical properties of plant fibers must be investigated in depth to determine if this natural parameter could have a significant impact on the variability.

To conclude about the effect of growth conditions, we think that the first mandatory research work to do is the determination of the optimal growth conditions in terms of humidity, temperature, watering, sun radiation, and fertilizers to reach the optimal mechanical properties of plant fibers at the different specific scale levels discussed earlier. The results of these optimizations could be then used to develop a smart cultivation system with artificial intelligence (AI) techniques. This smart system should be able to adapt the growth parameters to the optimal values depending on the actual climatic conditions of each season and each year. In this way, the mechanical properties of plant fibers should be not only stable but also optimized.

The extraction conditions as well as possible treatments before extraction can also affect the mechanical properties of plant fibers and the resulting composite. Indeed, and as shown in Ref. 19, a chemical treatment such as aqueous ammonia has shown its potential to reduce fiber damage during the extraction process, which leads to improving the mechanical properties of plant fibers. Ammonia treatment can modify cellulose crystalline packing and dissolve lignin in the biomass.20 The question here is as follows: is there any functional relationship between the treatment parameters and the variation of the chemical composition as well as the microstructure of plant fibers? Answering this question can bring some perspectives to use the chemical treatment with the aim of adjusting the micro-composition of plant fibers to control their mechanical properties.

Chemical treatment has been also used to improve the interface quality between plant fibers and the polymer matrix. Indeed, the effectiveness of the interface between plant fibers and the polymer matrix is subjected to different issues related to the presence of hydrophilic hydroxyl groups on the surface of plant fibers that are not compatible with the hydrophobic nature of the matrix.21 Several chemical treatments, such as alkaline treatment, have been developed and investigated on plant fibers to improve fiber adhesion properties with the polymer matrix.21,22 As an example, it has been shown that an alkaline treatment on flax fibers can increase the mechanical properties of flax fiber-reinforced epoxy composites in terms of tensile modulus and tensile strength by around 30%.23

Comments

Post a Comment